What are the challenges associated with wastewater odor in the environment?

High levels of hydrogen sulfide (H2S) are a nuisance to the surrounding community and often result in odor complaints, which can quickly escalate to commissioners, mayors, and other public officials.

Health and safety are also a big concern. When H2S levels reach 100 ppm or higher, it becomes an immediate threat to the health of plant employees per the OSHA guideline of NIOSH IDLH: 100 ppm1. If H2S is not monitored or controlled, it can generate methane as a byproduct, which has a lower explosive limit (LEL) of 5%.2

In addition to the atmospheric challenges of wastewater odor, H2S can cause significant corrosion to infrastructure as it condenses into sulfuric acid. This can corrode lift stations and other internal structures of the wastewater treatment plant (WWTP).

Treatment of wastewater odor can be challenging as the properties of the raw sewage change on a regular basis - from hour to hour, day to day, winter to summer, etc. These ever-changing conditions make it difficult to evaluate and treat the problem.

How do vapor phase technologies treat wastewater odor?

Odor and corrosion are treated using either 1) liquid phase products, 2) vapor phase products, or 3) recommend changes to the current system.

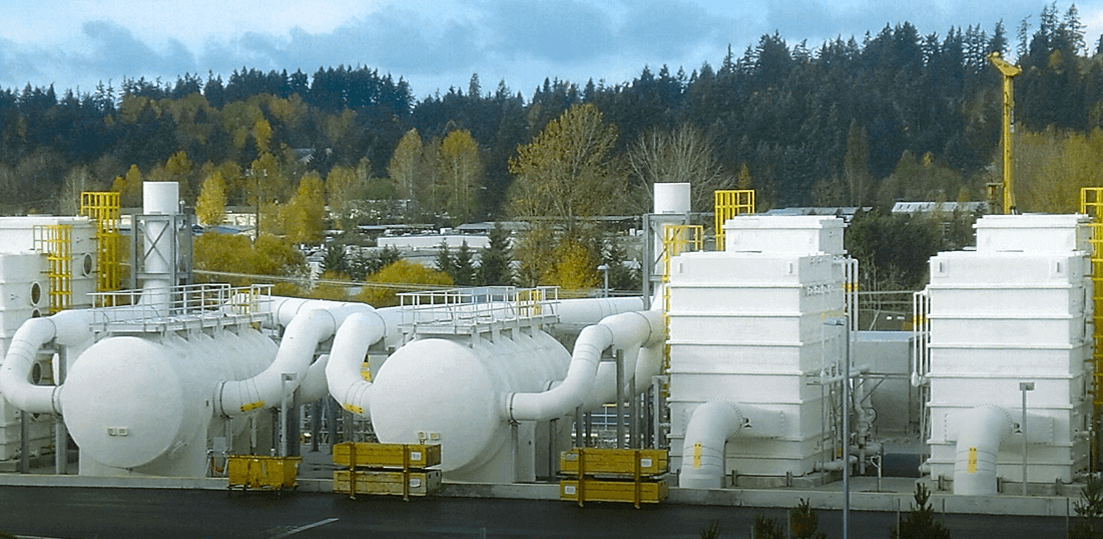

Vapor phase technology is typically used to treat a point-source issue where odorous compounds are released to the atmosphere. Vapor phase technology creates a vacuum on the structure and pulls foul air into the unit to remove the contaminants. Fresh air is then released into the atmosphere.

What are the best applications for vapor phase technologies?

The first step is to understand exactly what you are trying to treat. There may be underlying compounds present in addition to hydrogen sulfide. Different technology selection will be dependent on each odor profile.

Point-source treatment at the wastewater treatment plant or lift station is the most typical application for vapor phase technologies. Sites with highly turbulent flow will strip H2S out more than normal. A large drop of sewage, around 2-3 feet will also create more odor in the atmosphere than a quiescent flow. A well-designed vapor phase system will ensure that none of the odorous components are released and sites with multiple emission points in close proximity can be treated with a single unit.

What types of vapor phase technology are available?

Carbon Adsorption

Adsorber systems contain activated carbon that enable the transfer of contaminants onto media as the air stream passes through the vessel. The carbon needs to be removed and replaced once it reaches a specific saturation.

Biofiltration

Utilize biological processes for odor removal. The media bed is irrigated with water and nutrients to support biomass growth. As air passes through the unit, H2S and other odorous compounds are removed.

Bio-trickling Filters

Utilize sulfide-oxidizing bacteria to remove odors from the air. Biotrickling filters are able to handle high H2S concentrations and are well-suited to handle entire plant odors.

Chemical Scrubbers

Use chemicals such as sulfuric acid, caustic soda, and sodium hypochlorite to absorb and react with odors. Chemical scrubbers can be highly effective, but complicated to operate with frequent maintenance and chemicals costs.

What are the considerations for selecting the right system?

When selection a vapor phase system, the customer needs to primarily consider the H2S loadings, system size, and the location.

In my experience with vapor phase odor control solutions, residents typically don’t want to see it, hear it or smell it. Thus, a lower profile system would make more sense for a populated area.

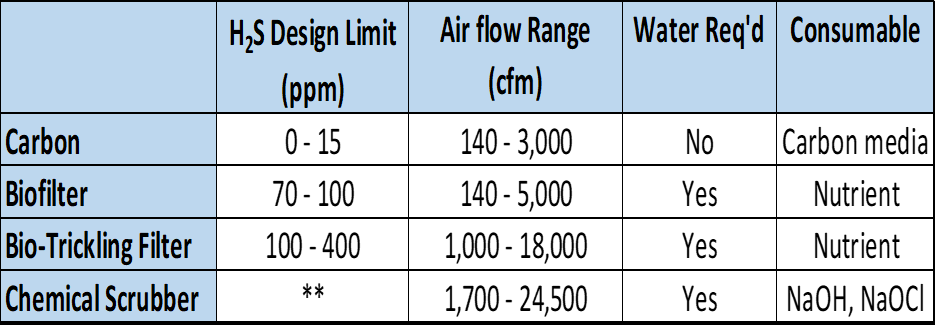

At the wastewater treatment plant there may be more flexibility for larger units, which can be cost-effective when treating higher loadings. The chart below compares the design characteristics of each of the four technologies.

Vapor Phase System Design Characteristics

**No defined upper limit. Increases in H2S loading require more caustic and bleach feed.

Evoqua’s approach to design includes extensive discovery including the chemistry of the wastewater, structure volume, available footprint, available utilities and the objectives of the application so our engineers can find the best fit solution for each specific application.

When does it make sense to combine technologies?

Often times a combined approach is more cost-effective and provides a redundant solution. Pre-treating the waste stream with a liquid phase solution can reduce H2S loadings, impacting the size and energy needed for a vapor phase system.

For example, if loadings are extremely high near a residential area, a liquid phase treatment can be used upstream of the control point. This will significantly reduce H2S levels prior to the vapor phase treatment so that a smaller biofilter can be used.

What are the maintenance and service requirements?

Most vapor phase systems require monthly maintenance at a minimum, but some are more complicated than others.

Carbon adsorption systems are the simplest to maintain and are monitored monthly and sometimes daily to determine when to replace the carbon. Biofilters require monthly maintenance to evaluate the nutrients, bed and spray pattern from the nozzles. For bio-trickling filters in the 20-foot range or larger, we monitor the water flow, nutrient levels and pH range on a monthly basis.

Chemical scrubbers are the most complicated to operate and need to be monitored on a weekly basis to update the pH set point and packing. In addition, the packing should be acid washed every month or more frequently with higher loadings. If not supervised closely, the bed can start to foul and create problems with elemental sulfur deposits.

How can Evoqua help?

Evoqua has a variety of service programs to meet your needs. We can also provide full-service options including equipment, maintenance, proactive service and expendables.

Mike Murphy

References:

1. https://www.osha.gov/hydrogen-sulfide/hazards

2. https://www.osha.gov/sites/default/files/publications/OSHA3843.pdf