Hydrogen Production

The future energy mix is evolving and Magneto’s anodes are playing a vital supporting role

Magneto® special anodes are the heart of green hydrogen production for a low carbon future

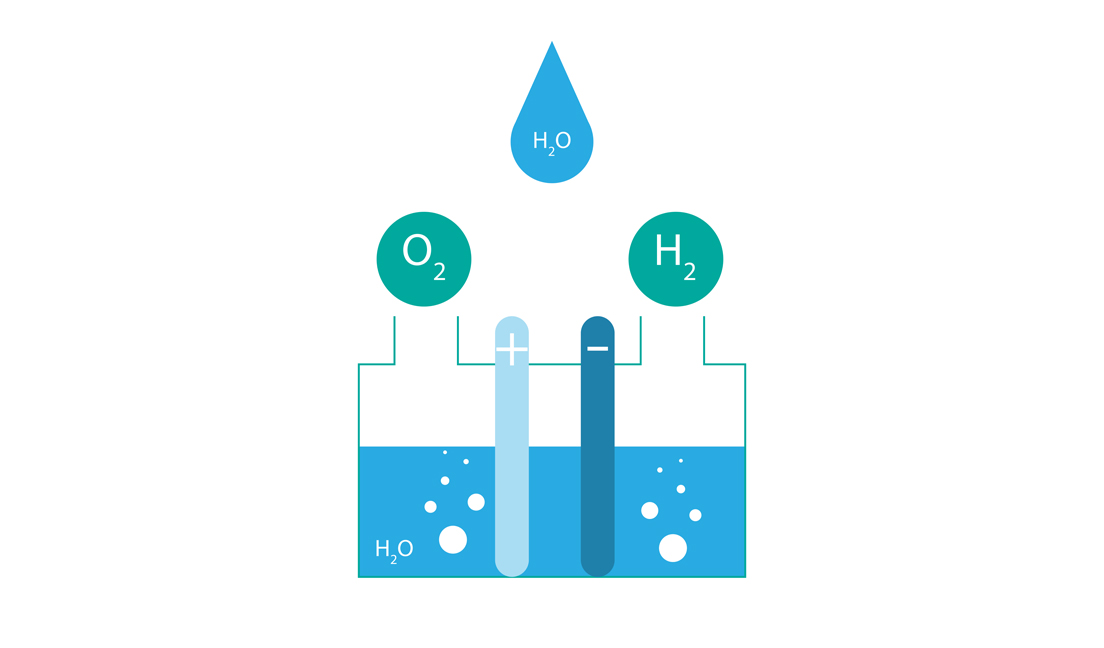

Green hydrogen is hailed as one of the keys to a low carbon energy future worldwide. But for it to be a success on the scale needed, production must be highly efficient so the levelized cost of green hydrogen is viable.

The key to achieving efficiency is having the right technology solutions in place. At the heart of the green hydrogen production process is the anode and cathode used as catalysts in the electrolysis process, get these right and you will reap significant operational and cost benefits. Having the right coating on these is can make the difference in efficiency and production rate.

Introducing the newest PGM-free coatings for AWE green hydrogen applications:

- Intensify production while maintaining efficiency

- Up to 4x production rate without efficiency loss compared to SoA

- PGM-free Magneto coatings can be economically scaled up to GW/a capacity

- Optimized for performance and durability

Technology Solutions for Green Hydrogen Production

Find out how our industry leading solutions are helping to improve the levelized cost of green hydrogen

Watch NowAs a leading global provider of electrochemical process solutions, we have over six decades of experience in designing and manufacturing superior coatings that offer outstanding performance, efficiency, and longevity.

Our latest advanced coatings for anodes and cathodes are revolutionizing green hydrogen production as they don’t contain precious metals and can operate at 4 times the capacity of traditional electrodes.

Green Hydrogen Infographic

Explore our comprehensive range of water treatment solutions offered for each step of the process

Download NowThis is helping to increase the accessibility of green hydrogen production and lower costs. The coating process allows different form factors such as plate, expanded metal, and felts and foams to be coated with an electrocatalyst or contact coating.

For water electrolysis stack manufacturers who need intensification of hydrogen production, Evoqua’s advanced, patented, and durable electrodes provide up to halving of initial capital and fixed operational costs unlike non-activated electrodes as proven by operational references.