THE CUSTOMER:

A major bottled water manufacturer in southern California engaged with Evoqua to configure a disinfection and delivery system with specific process requirements.

THE CHALLENGE:

The customer had the following requirements for dissolved ozone measurement in the contact tank at normal and varying production flow rates:

- Purified Water target range at 250 ppb (+/- 50 ppb)

- Spring Water target range at 100 ppb (+/- 20 ppb)

- Ozone Off Gas at the Skid/Ozone System below 0.1 ppm

- Ambient Ozone Monitor pre-programmed to warn at 0.1 ppm

- (OSHA Time Weighted Limit is 0.1 ppm for 8 hours)

In addition to the above technical specifications, the customer was looking to upgrade to a more modern and efficient solution that could help them:

- Meet Purified Water and Spring Water Residual Targets

- Keep Ozone Off Gas Below Minimum Levels

- Reduce Production Downtime

- Add Precision Monitoring and Control

- Improve Employee Safety

SOLUTION:

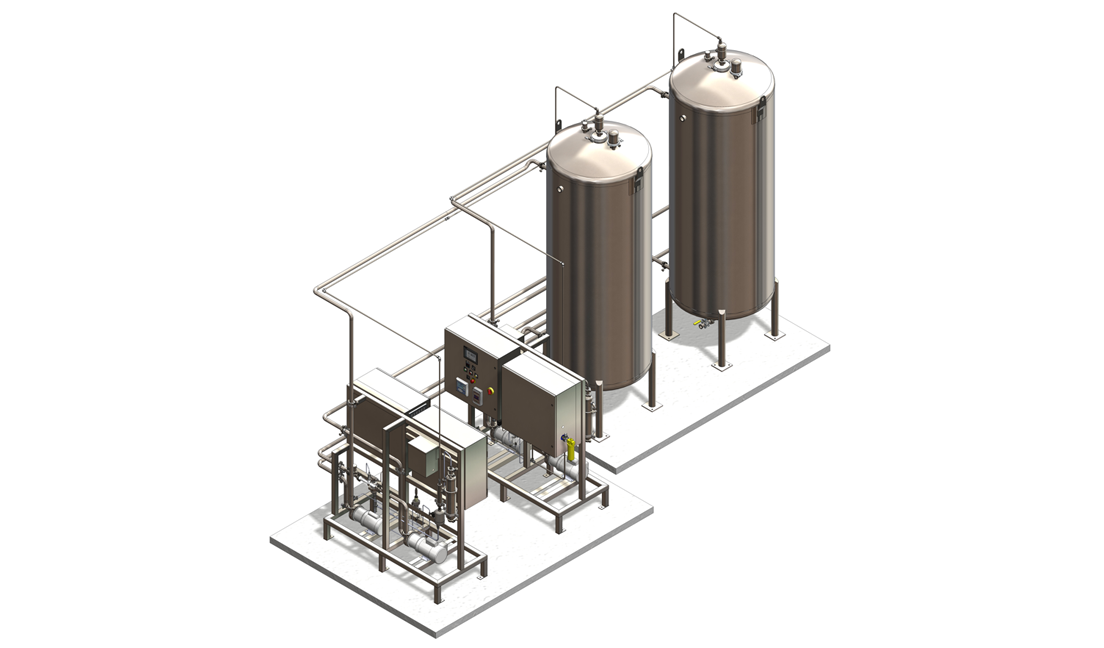

The Pacific Ozone PGS Series packaged system is designed with known performance characteristics to meet and exceed rigorous user requirement specifications. They are complete and self-contained to maximize the ease of integrating into a bottling line process. By mastering the science of ozone generation and applications, Evoqua delivered a safe, proven, qualified solution with high-performance and trouble-free disinfection for bottled water and beverage production.

This system was comprised of:

- 2 x PGS Series Packaged Ozone Generator Systems

- Oxygen Concentrators

- Ozone Generation

- Standard Software Platform and Touch Screen HMI

- Precision Dissolved Ozone Control

- Ambient Ozone Monitoring with Safety Interlock

Complete Packaged Ozone Systems offer greater reliability and efficiency using best practices for ozone treatment making them ideal for mission critical bottled water and beverage applications.

RESULTS:

With the provided energy efficient solution, the customer was able to meet all their project goals, in addition to benefitting from:

- Quick and Seamless Integration

- Superior Disinfection Results

- Process Control of All Critical Parameters

- Full Monitoring in Real-time

- More Process Uptime

- Reduced Maintenance Time

- Reduced Product Loss

Think your bottled water operation could benefit from a similar solution? Contact us today for an evaluation and custom quote to upgrade your existing bottled water system.

Evoqua Ozone Generation systems undergo factory acceptance testing to ensure they are capable of producing the desired ozone concentration, based on operational parameters outline in the Operating Manual. System performance of microorganism inactivation depends on the CT value, pH, and temperature of water. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com