Inactivate pathogens, remove contaminants, meet sustainability objectives, and more!

UV is a proven, safe, and reliable method of disinfection for municipal drinking water, wastewater, and reuse water. The highly efficient and sustainable process does not involve the use of added chemicals and reduces the risk of disinfection by-products by lowering chemical disinfection requirements. It is effective as both a primary and secondary barrier disinfectant. UV is also widely used as part of a multi-barrier treatment strategy, used as the primary disinfectant, followed by the addition of residual chlorine to protect the treated water throughout the distribution network.

WHAT IS ULTRAVIOLET LIGHT?

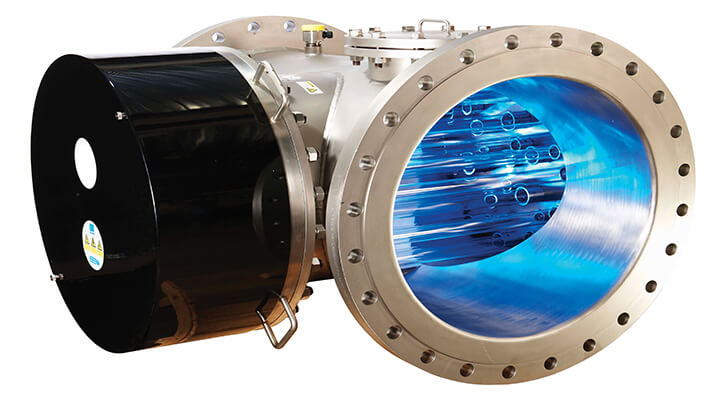

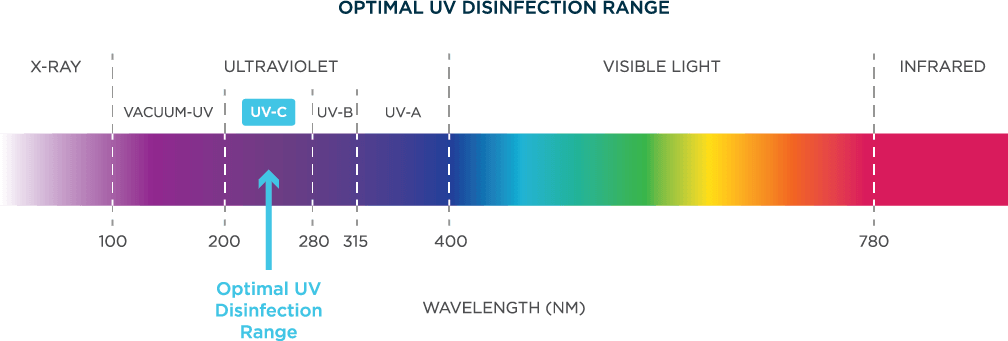

Ultraviolet (UV) light is energy within the electromagnetic spectrum that has shorter wavelengths than that which are visible to the human eye. UV light is a range of electromagnetic waves from 100 to 400 nanometers (between x-ray and visible light). The division of UV light is classified as Vacuum UV (100–200 nm), UV-C (200–280 nm), UV-B (280–315 nm) and UV-A (315–400 nm). The energy waves provided in the UV-C spectrum demonstrate germicidal efficiencies that provide highly effective disinfection.

HOW UV DISINFECTION WORKS

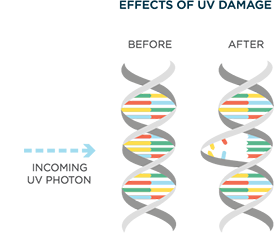

UV light provides effective inactivation of microorganisms such as bacteria, viruses, molds and other pathogens without the use of chemicals. UV light works by causing damage to the DNA or RNA found in all living species. Once the DNA becomes damaged, or dimerized, organisms, such as Cryptosporidium or E. Coli, are unable to carry out the routine cell functions of respiration, the assimilation of food and replication. Once the cell is rendered non-viable the organism quickly dies.

UV light provides effective inactivation of microorganisms such as bacteria, viruses, molds and other pathogens without the use of chemicals. UV light works by causing damage to the DNA or RNA found in all living species. Once the DNA becomes damaged, or dimerized, organisms, such as Cryptosporidium or E. Coli, are unable to carry out the routine cell functions of respiration, the assimilation of food and replication. Once the cell is rendered non-viable the organism quickly dies.ADVANTAGES OF UV DISINFECTION

for Municipal Drinking Water

for Municipal Drinking Water

![]() Proven solution against microorganisms such as cryptosporidium and giardia

Proven solution against microorganisms such as cryptosporidium and giardia

![]() Safe, low-risk technology and easy to operate

Safe, low-risk technology and easy to operate

![]() Easy to install and retrofit into existing plants

Easy to install and retrofit into existing plants

![]() Highly efficient technology reduces CAPEX

Highly efficient technology reduces CAPEX

![]() Simple and low maintenance technology reduces OPEX

Simple and low maintenance technology reduces OPEX

![]() Independent 3rd party validated performance to US EPA UVDGM and NSF61

Independent 3rd party validated performance to US EPA UVDGM and NSF61

for Municipal Wastewater and Reuse

for Municipal Wastewater and Reuse

![]() Simple to install, easy to operate technology

Simple to install, easy to operate technology

![]() Enhanced safety features and reduced maintenance requirements

Enhanced safety features and reduced maintenance requirements

![]() Validated to USEPA UVDGM

Validated to USEPA UVDGM

![]() Validated to the 2003 & 2012 NWRI Reuse Guidelines

Validated to the 2003 & 2012 NWRI Reuse Guidelines

![]() Applications include disinfection, photolysis, and advanced oxidation

Applications include disinfection, photolysis, and advanced oxidation

Chemical-free disinfection, with

Compact, and compliant solutions, while

Reducing OPEX and CAPEX

Worldwide Impact

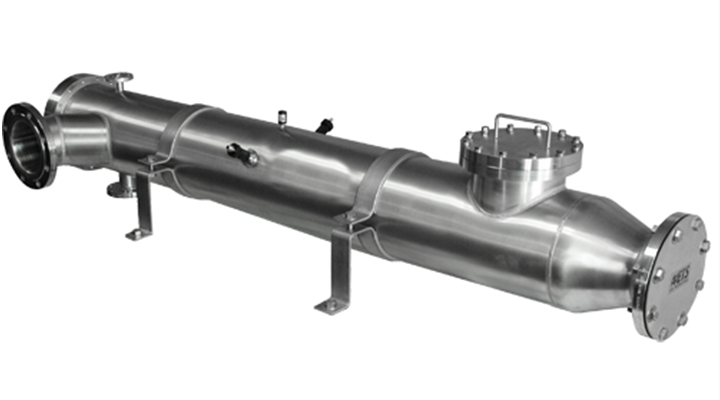

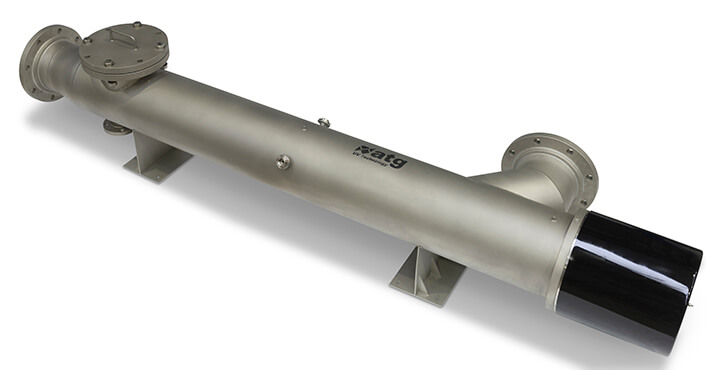

Evoqua UV disinfection generator systems undergo third-party validation testing in accordance with the UVDGM (USEPA, 2006). Validated products are tested to confirm a minimum inactivation equivalent of 3 log (99.9%) for microorganisms in accordance with NSF/ANSI 50 and the UVDGM. Performance is not claimed nor implied for any product not yet validated; unvalidated products use single point summation calculations to provide delivered dose recommendations. Performance limitations depend on feed conditions, overall installed system design, and operation and maintenance processes; please refer to Operations Manuals. For more information: Contactus@evoqua.com